How to Properly Remove Rubber Lining from a Tank

When it’s time to repair, re-line, or repurpose an industrial tank, one of the most critical steps is removing the existing rubber lining. While this may sound simple, the process can be delicate. Knowing how to remove rubber lining correctly is important in order to protect the substrate underneath, ensure worker safety, and prepare the tank for a new, long-lasting lining system.

Below, we’ll walk through the steps involved in rubber lining removal, explore common methods, and explain why hiring a professional rubber lining contractor is the smartest and safest choice for any tank rehabilitation project.

Why & When Rubber Lining Removal Is Necessary

Rubber linings are designed to protect metal tanks and equipment from corrosion, abrasion, and chemical attack. However, over time, exposure to harsh environments, mechanical wear, or chemical degradation can cause the lining to lose integrity. When that happens, the tank must be stripped and re-lined to restore protection and extend its service life.

In other cases, removal may be required when a tank is being repurposed for a new application, especially if the existing rubber compound isn’t compatible with different stored materials.

The Challenges of Stripping Cured Rubber

Cured rubber is engineered to be incredibly durable, which makes it equally tough to remove. It forms a strong, often vulcanized bond to the substrate that resists mechanical and chemical attack. As a result, stripping rubber lining is a time-consuming and labor-intensive process that requires specialized tools, trained technicians, and careful surface preparation.

Improper removal can easily damage the substrate material, leading to pitting, gouging, or contamination that will compromise the adhesion of the new lining. Additionally, heat, dust, and fumes generated during removal can pose serious health and safety hazards if not managed properly.

Safe and Effective Rubber Lining Removal Methods

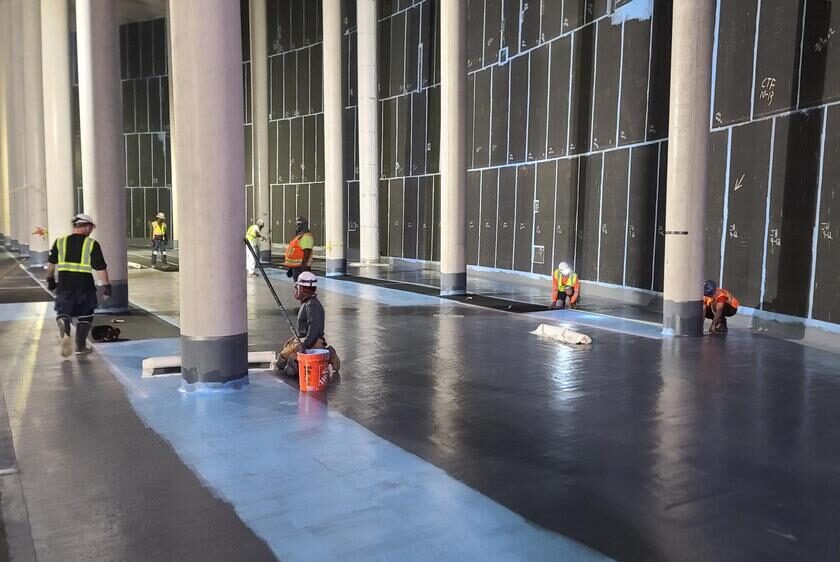

Several techniques can be used to remove cured rubber, depending on the thickness of the lining, the type of adhesive used, and the condition of the substrate. Professional lining contractors typically rely on one or a combination of the following methods.

1. Mechanical Removal

Mechanical removal uses tools like pneumatic chisels, scrapers, grinders, or abrasive blasting systems to physically strip the rubber from the tank surface. This method is highly effective for thick or heavily bonded linings but requires skill to avoid damaging the underlying substrate.

In some cases, cryogenic methods (using extreme cold to embrittle the rubber before removal) can also make mechanical stripping easier.

2. Chemical Removal

Chemical stripping involves applying solvents or specialized agents that break down the adhesive bond between the rubber and the substrate. While effective in some cases, this approach must be handled carefully due to potential for hazardous fumes and chemical reactions. It’s generally only used when mechanical methods are impractical or risk causing physical damage to the substrate.

3. High-pressure or Hydroblasting Techniques

High-pressure water blasting (also known as hydroblasting) uses jets of water at extremely high pressure to peel away rubber lining material without generating dust or heat. This method is particularly useful for removing rubber from tanks used in chemical or food-grade applications, as it helps maintain a clean, low-contaminant surface.

Protecting the Substrate During Removal

We can’t iterate enough that it’s important to preserve the condition of the substrate material during rubber lining removal. Any damage or surface irregularities can interfere with adhesion and performance of the new lining.

Professionals use precise removal tools, controlled heat and cold, and specialized surface preparation techniques to ensure that the substrate remains intact. Once the old lining is removed, the tank is typically cleaned, inspected, and blast-prepared to achieve the correct surface profile before the new rubber lining is applied.

This high attention to detail helps ensure the new lining bonds properly, performs effectively, and provides years of reliable protection.

Partner with the Experts in Rubber Lining Removal

Properly removing rubber lining from a tank requires more than brute force. It takes precision, experience, and the right safety protocols. Whether you’re preparing for re-lining or converting a tank for a new application, professional removal can ensure the job is done safely, efficiently, and to industry standards.

To discuss your removal project and discover how the US RUBBER team can help extend the life and performance of your next lining, contact us online.