Choosing a rubber lining contractor is a crucial decision for asset protection. Yet many industrial teams are forced to evaluate rubber lining companies that appear similar on the surface.

The reality is that not all rubber lining companies are built the same, and the differences often don’t become apparent until a lining fails in service.

When the wrong contractor is selected, the consequences are real:

- Premature lining failure

- Corrosion develops beneath the lining

- Unplanned downtime and costly rework

- Safety, compliance, and inspection issues

The most reliable way to evaluate rubber lining companies is to look beyond price and lead time and focus on the technical and quality-driven factors that directly impact performance.

This article outlines 10 critical criteria engineers should never overlook. Together, these factors separate basic tank lining contractors from true technical partners.

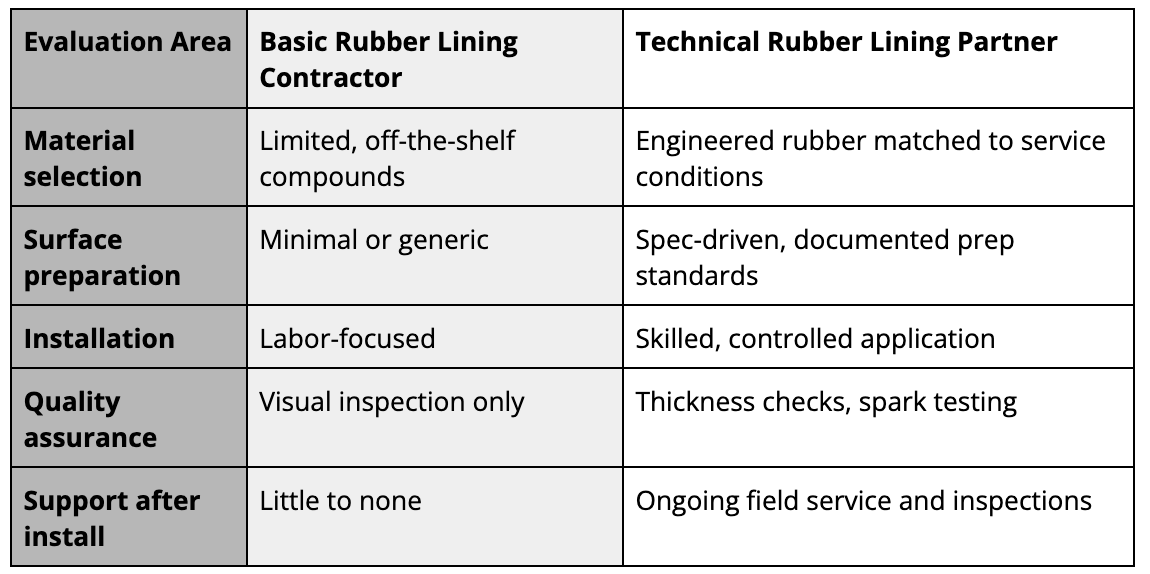

Basic Rubber Lining Contractor vs. Technical Rubber Lining Partner

Here’s a quick reference table to help you compare the differences between various rubber lining companies.

Understanding these differences upfront can help prevent failures that only become visible after a tank is back in service.

Now let’s dive in deeper.

10 Must-Have Qualities of Superior Rubber Lining Companies

These must-have qualities define what truly sets superior rubber lining companies apart — and directly impact tank performance, service life, safety, and overall project success.

1. Proven Experience in Your Specific Industry and Application

The performance of rubber lining depends heavily on real-world operating conditions, making industry-specific experience crucial.

Why industry experience matters:

Different industries expose tanks to very different stressors:

- Chemical processing: aggressive chemicals, elevated temperatures

- Mining: abrasion, solids, impact loading

- Water treatment: continuous immersion, variable pH

- Power & utilities: thermal cycling, long service intervals

- Rail & transportation: vibration and movement

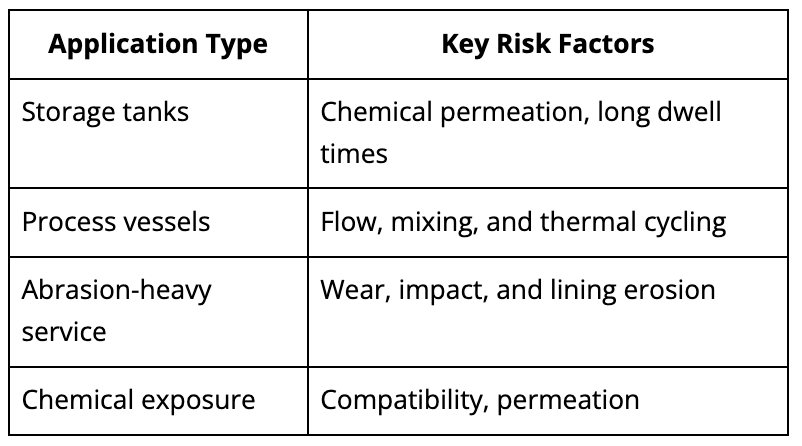

Rubber lining application differences that matter:

Red flag to watch for:

Rubber lining offered as an add-on service by general coating contractors often signals limited expertise and inconsistent QA.

What to look for:

- Case studies in similar industries

- Experience with comparable temperature, pH, and solids

- Clear explanations behind material and system selection

2. Rubber Material Quality and Formulation Options

Not all rubber compounds perform the same — material selection directly impacts service life.

Key material considerations:

- Natural vs. synthetic rubber

- Chemical resistance

- Abrasion resistance

- Temperature tolerance

Why it matters:

Off-the-shelf materials often fail prematurely in aggressive environments.

Do all rubber linings use the same materials?

No — rubber formulation directly impacts durability and performance.

3. Lining Thickness Control and Specification Accuracy

Thickness plays a major role in wear life, impact resistance, and chemical protection.

Why thickness matters:

- Extends service life

- Improves impact and abrasion resistance

- Reduces chemical permeation

Common mistakes:

- Inconsistent thickness across the tank

- Over- or under-specifying based on assumptions

What professionals provide:

- Application-specific thickness recommendations

- Verification checks during installation

4. Top-Notch Surface Preparation and Bonding Systems

Surface preparation is one of the leading causes of lining failure.

Critical prep elements:

- Proper blasting profiles

- Cleanliness standards

- Engineered primer and bonding systems

5. Rubber Lining Installation Expertise and Controlled Application Methods

Rubber lining is a specialized trade, not a simple install.

What matters during installation:

- Trained, experienced crews

- Controlled application environments

- Consistent techniques and seam quality

Risks of inexperienced installers:

- Air pockets

- Weak seams

- Poor adhesion points

6. High-Quality Cure Methods and Environmental Control

Curing directly affects adhesion strength and long-term durability.

Cure methods compared:

What top-tier companies manage:

- Temperature

- Humidity

- Cure time validation

7. Rubber Lining Inspection and Testing Capabilities (Including Spark Testing)

Quality assurance doesn’t stop when installation ends.

Essential inspection methods:

- Visual inspection

- Thickness verification

- Spark testing

Do rubber linings need to be tested after installation?

Yes — spark testing verifies rubber lining integrity before the tank enters service.

8. Quick Turnaround Time and Organized Project Coordination

Yes, downtime is costly — but rushing a lining job can create long-term failures.

What to evaluate:

- Realistic, achievable timelines

- Coordination with outages and shutdowns

- Ability to scale crews when needed

Red flag:

Unrealistically short schedules that bypass QA steps.

9. Adherence to Safety Standards and Compliance Practices

Rubber lining often involves confined spaces and hazardous conditions.

What serious contractors prioritize:

- OSHA compliance

- Documented safety programs

- Trained, safety-certified crews

Strong safety performance reflects overall operational discipline.

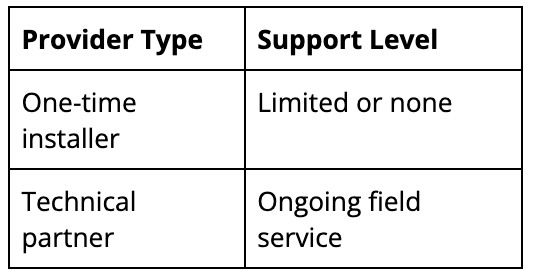

10. Field Service Support and Long-Term Partnership

Rubber lining is not always “install and forget.”

Value-added support to look for:

- Field inspections

- Repairs and touch-ups

- Emergency response capabilities

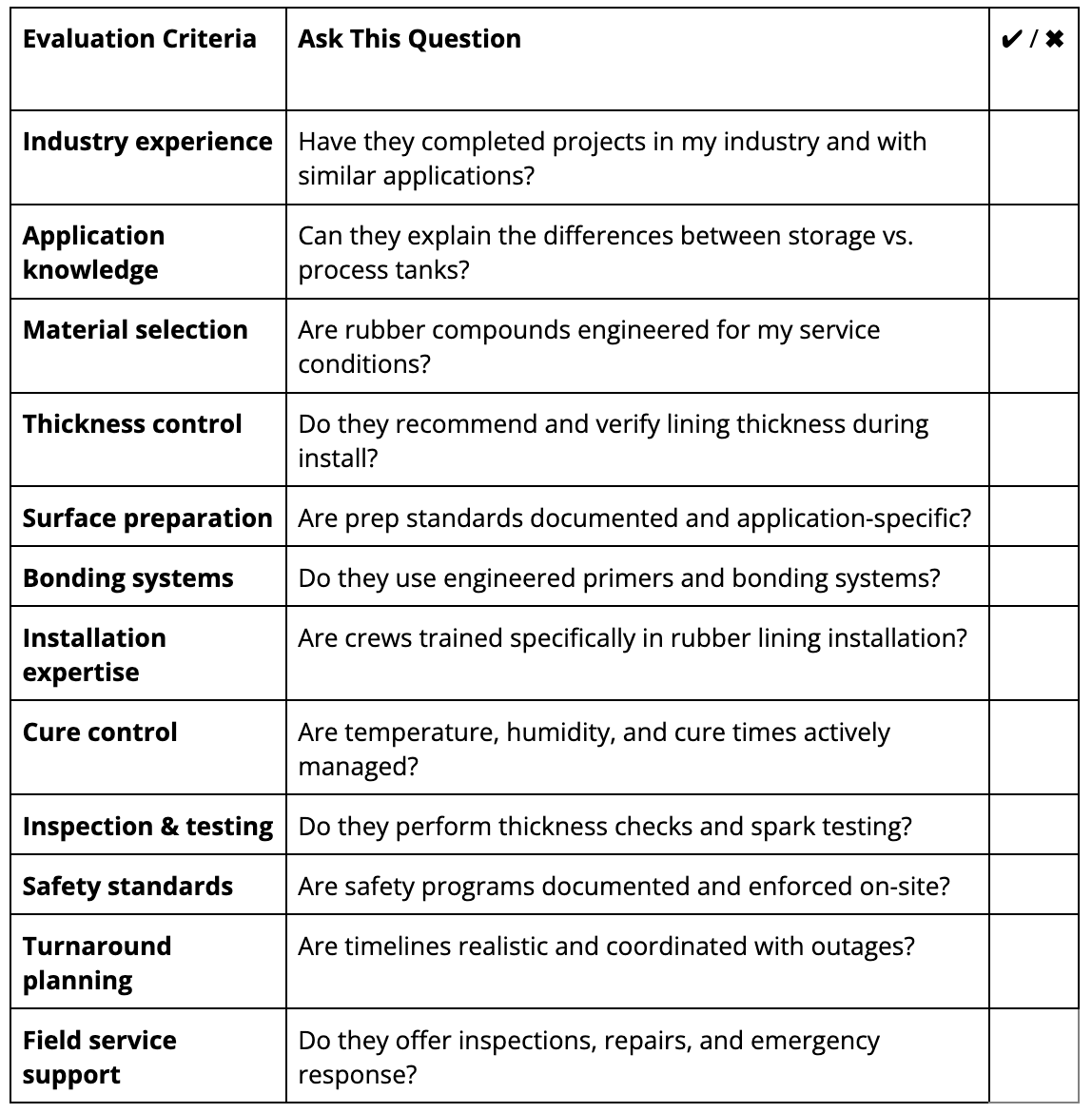

Rubber Lining Companies: Final Evaluation Checklist

Use this checklist when comparing rubber lining companies to quickly identify whether you’re working with a basic contractor or a true technical partner.

Rubber Lining Company Comparison Checklist:

If a rubber lining company cannot confidently answer several of these questions (or avoids providing documentation), that’s a strong indicator that they may be operating as a general contractor, rather than a specialized rubber lining provider.

Rubber Lining Companies FAQ:

Q. What should I look for in rubber lining companies?

A. Look for industry-specific experience, engineered material selection, controlled installation and curing, formal inspection and testing, strong safety standards, and long-term field support.

Q. How long does industrial rubber lining last?

A. Industrial rubber lining typically lasts 10–20 years or more, depending on service conditions, material selection, thickness, and installation quality.

Q. Is spark testing required for rubber linings?

A. Spark testing is not always required, but it is strongly recommended to detect pinholes and defects before a tank enters service.

Q. What industries require rubber-lined tanks?

A. Rubber-lined tanks are commonly used in chemical processing, mining, water and wastewater treatment, power generation, rail, steel, battery manufacturing, and other industrial applications.

How US RUBBER Sets the Standard Among Rubber Lining Companies

The 10 evaluation factors outlined above reflect the same principles US RUBBER applies to every project. Rather than treating rubber lining as a one-time install, we approach each job as a critical asset protection system. We take pride in our:

- Engineered materials selected based on real service conditions, not generic assumptions

- Skilled installation teams dedicated to rubber lining applications

- Robust QA and testing, including thickness verification and spark testing

- Safety-first culture aligned with industrial and regulatory requirements

- Long-term customer relationships supported by field service and repair capabilities

This approach positions US RUBBER as a technical partner for high-risk, high-performance applications — not a low-bid vendor focused solely on speed or price.

Choosing the Right Rubber Lining Company Protects More Than Your Tank

Selecting the right rubber lining company impacts more than initial installation costs. It affects uptime, safety, compliance, and the long-term reliability of critical equipment.

When evaluating rubber lining companies, the most successful teams:

- Ask better, application-specific questions

- Demand documented quality assurance and testing

- Work with experienced specialists who understand their operating environment

Ready to Talk Through Your Application?

Talk to US RUBBER about your tank, vessel, or lining requirements — or request a quote to ensure your rubber lining system is built for long-term performance.