When it comes to protecting industrial tanks, you have options. Some facilities install rubber lining from day one to protect against corrosion or chemical attacks. Others look into lining later, when a tank starts showing signs of wear. Either way, one question always comes up when maintenance is due: Is it more cost-effective to line (or reline) the tank or just replace it?

The answer isn’t always obvious. Sure, a brand-new tank sounds nice, but it comes with a hefty price tag and often more downtime than expected. So in this article, we’ll break down the total cost of ownership between rubber lining or total tank replacement. We’ll look at upfront costs, maintenance, service life, downtime, and long-term value so you can plan ahead or deal with a current issue with confidence.

Understanding Total Cost of Tank Ownership

Total cost of ownership (TCO) is a financial estimate that helps evaluate the direct and indirect costs associated with a product or system throughout its life cycle. In the context of industrial tanks, TCO can include:

- Initial purchase or repair cost

- Installation and labor

- Downtime during repair or replacement

- Ongoing maintenance

- Expected service life

- Performance and ROI

Upfront Cost Comparison: Tank Replacement vs. Rubber Lining

Tank Replacement: Replacing an entire tank requires significant capital investment, including:

- New tank fabrication (steel, concrete, or alloy)

- Freight and logistics

- Permitting and regulatory compliance

- Installation and foundation work

- Disposal of old equipment

Depending on size and material, replacement costs can run into the hundreds of thousands of dollars per tank.

Rubber Lining Installation: Rubber lining a tank costs a fraction of replacement, particularly for tanks where the shell is still structurally sound. Some expenses you might have are:

- Surface preparation (blasting, cleaning)

- Rubber lining materials

- Installation labor

- Curing and inspection

Often at 40-70% less than replacement, rubber lining is more economical upfront to restore protection. An example scenario would be: a 10,000-gallon carbon steel tank costs ~$150,000 to replace, but can be relined for ~$50,000 using high-performance rubber lining.

Service Life & Durability

When properly applied and maintained, rubber linings can help tanks last 10–20 years or longer, depending on:

- Type of rubber used

- Service environment (temperature, pressure, chemical exposure)

- Application quality and curing process

Tank Maintenance and Inspection Requirements

Rubber lined tanks are:

- Easier to inspect because the linings can be visually and spark-tested.

- Easier to repair because localized damage can usually be patched without relining the entire tank.

- Cheaper to maintain because there isn’t a need for recoating every few years like with some epoxy or paint coatings.

New tanks (without rubber lining):

- May require protective coatings anyway, especially for carbon steel.

- Offer great corrosion resistance but are much more expensive and can still suffer pitting or stress corrosion over time.

Downtime and Production Impact

One of the most important things to account for when making the decision between rubber lining and tank replacement is expected downtime.

Tank replacement can take weeks or months because it requires decommissioning, demolition, site prep, installation, testing, and ramp-up. Each day offline can cost thousands in lost production.

Rubber lining installation can often be completed in a matter of days, especially by experienced crews.

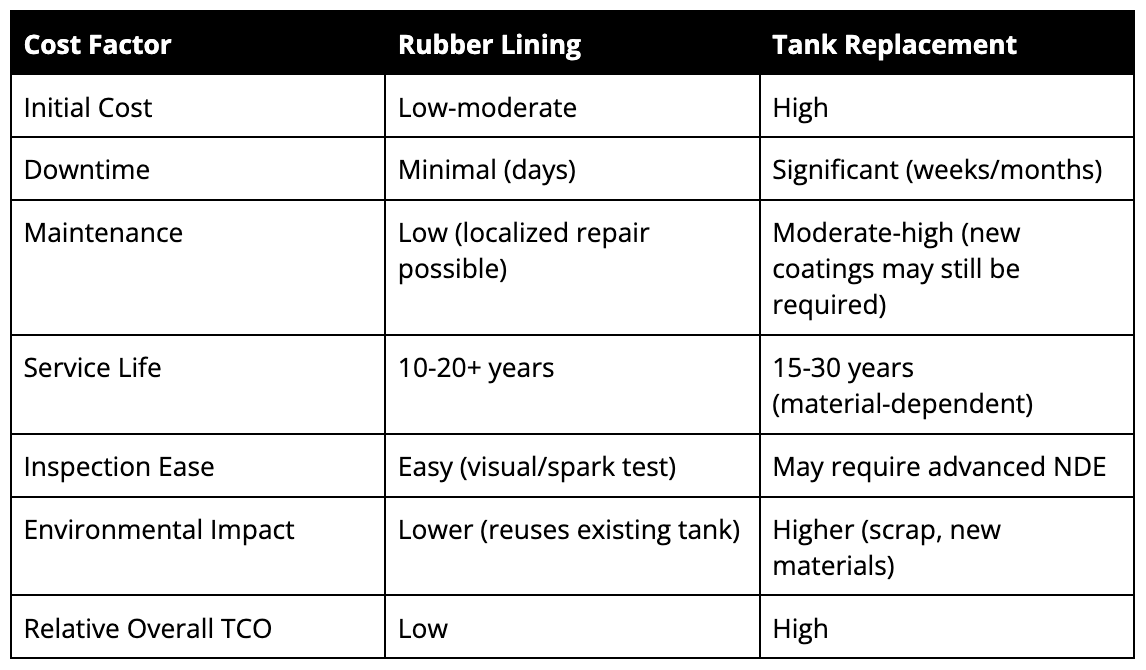

Total Cost of Ownership Comparison Chart

The Advantage of Rubber Lining Is Long-term ROI

While new tanks may last slightly longer in some cases, the cumulative cost savings of rubber lining — combined with faster return to service — typically results in a higher ROI over the tank’s lifespan.

Some additional benefits are:

- Customization – Rubber lining can be tailored for chemical resistance, abrasion, or thermal stability.

- Sustainability – Relining extends the life of existing infrastructure, supporting any company-wide ESG goals.

- Flexibility – Tanks can be relined again in the future, so you could delay full tank replacement sometimes indefinitely.

When Tank Replacement Does Make Sense

There are some situations where replacement may be the better long-term option.

- Severe structural damage, like cracks or wall thinning, that rubber lining can’t help

- Significant deformation or pressure integrity issues

- Regulatory changes requiring full design updates

But for most corrosion or chemical wear cases, rubber lining is the more economical, lower-risk solution.

Maximize ROI with Rubber Lining from US RUBBER

At US Rubber, our team specializes in rubber lining installation, repair, and NACE-certified inspection services for tanks, vessels, and piping systems. With decades of experience across industries — from chemical processing to water treatment — we help facility owners extend the life of their equipment, reduce costs, and improve safety.

Let’s work together to extend the life of your tanks without draining your capital.