How Often Should Tank Lining Be Inspected?

Maintaining the integrity of storage tanks and other vessels is paramount to ensure the safety of both personnel and the environment. Tank linings play a crucial role in preventing corrosion, leaks, and contamination of stored materials. To uphold these safety standards, the American Society of Mechanical Engineers (ASME) provides guidelines on the frequency of tank lining inspections.

The Importance of Tank Lining Inspections

Tank linings serve as a protective barrier between the stored material and the tank’s substrate, preventing corrosion and ensuring the longevity of the structure. Over time, environmental factors, chemical exposure, and general wear and tear can compromise the integrity of tank linings, leading to potential hazards.

Regular inspections are vital to identify any issues promptly and implement necessary repairs or replacements. The frequency of these inspections is dictated by industry standards, with ASME playing a pivotal role in establishing guidelines to maintain the safety and reliability of industrial tank systems.

ASME Requirements for Tank Lining Inspections

ASME has developed a set of standards to govern the inspection and maintenance of industrial tanks, emphasizing the importance of routine assessments to detect potential problems before they escalate.

ASME Section VIII, Division 1

This code outlines the requirements for the design, fabrication, inspection, testing, and certification of pressure vessels. It includes guidelines for tank linings and their inspection intervals based on factors such as the nature of the stored material and the operating conditions.

API 653

While not directly under ASME, API 653 is a widely recognized standard for the inspection, repair, alteration, and reconstruction of aboveground storage tanks. ASME refers to API 653 for guidance on assessing the condition of tank linings, especially for tanks storing petroleum products.

How to Determine the Frequency of Tank Lining Inspection Intervals

ASME generally recommends inspections at regular intervals, typically ranging from one to five years. However, the frequency of tank lining inspections is influenced by a few factors.

Factors Influencing Inspection Intervals

- Corrosiveness of the stored material: Tanks storing corrosive substances may require more frequent inspections.

- Operating conditions: Tanks subjected to extreme temperatures, pressure variations, or mechanical stresses may need more frequent assessments.

- Environmental conditions: Exposure to harsh environmental elements can accelerate the deterioration of tank linings, necessitating more frequent inspections.

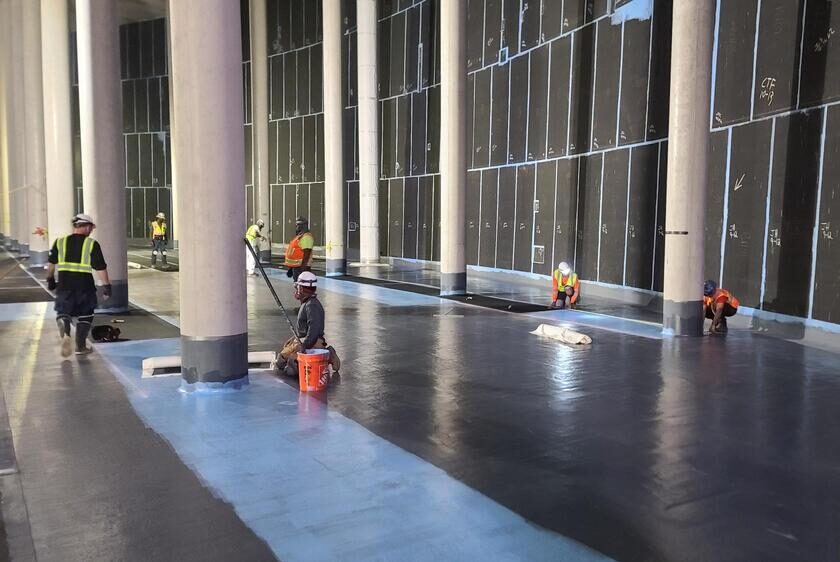

Contact US RUBBER for Tank Lining Services

Ensuring the integrity of tank linings is a critical aspect of industrial safety and regulatory compliance. By adhering to ASME standards, you can establish a comprehensive and systematic approach to tank lining inspections, safeguarding both your assets and the surrounding environment. Regular assessments, as outlined by ASME guidelines, help identify potential issues early on, allowing for timely maintenance and ensuring the long-term reliability of industrial tank systems.

If you need help conducting tank lining inspections or installing new tank lining altogether, get in touch with our team. As experts in the rubber lining space, we’re here to help ensure your projects are safe and durable for years to come.