In industries that rely heavily on tanks, vessels, and pipelines to store and transport materials, rubber lining is essential in extending the equipment’s life. This article explores some of those industries and related applications, and why rubber lining is a critical resource.

Top 9 Rubber Lining Industries and Applications

Rubber lining is applied to the interior surface of tanks, vessels, pipes, and other industrial equipment to protect against abrasion, corrosion, and chemical degradation. Not only does this make the equipment last longer, but it also ensures a safe environment and lowers maintenance costs (not to mention, the lost profit from operational downtime that inspection and maintenance requires).

So, here are several key industries that rely on rubber lining to maintain smooth operations.

1. Petrochemical Industry

Biggest threat: Chemical corrosion

The petrochemical industry is one of the largest consumers of rubber linings. Facilities in this sector handle corrosive chemicals like sulfuric acid, hydrocarbons, and caustic solutions, all of which can quickly erode unprotected tanks and pipelines. Applying rubber lining in chemical storage tanks and reaction vessels is necessary to provide a robust layer of defense against chemical attacks.

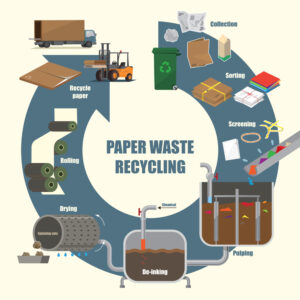

2. Pulp & Paper Industry

Biggest threat: Chemical corrosion and material abrasion

The pulp and paper industry faces significant challenges due to the abrasive nature of the pulp and the corrosive chemicals used in paper production. Chlorine, caustic soda, and other bleaching agents can rapidly degrade the steel surfaces of the tanks and vessels that house them. By applying rubber linings, facilities in this sector can protect against chemical corrosion and pulp abrasion.

3. Railcar Applications

Biggest threat: Chemical corrosion and material abrasion

Transporting chemicals and other industrial liquids via railcar is a high-risk endeavor. Rubber linings are used to protect the interior surfaces of the railcars that carry corrosive or abrasive materials.

Some rubber lining contractors offer customized solutions for railcar operators, which ensure the linings are compatible with the specific cargo being transported. This helps prevent leaks, contamination, and corrosion.

4. Nuclear Industry

Biggest threat: Radioactive exposure

The nuclear industry requires robust, fail-safe systems for handling radioactive materials and hazardous waste. Even the slightest material failure can result in catastrophic consequences, so rubber linings are used in chemical storage tanks and processing equipment to protect against radiation, corrosion, and chemical exposure.

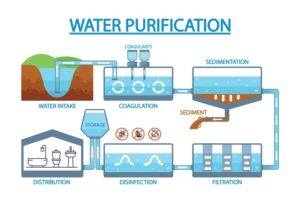

5. Water Treatment Plants

Biggest threat: Chemical corrosion and microbial growth

The water treatment industry relies on rubber linings, particularly in water treatment tanks and pipelines. Wastewater treatment plants use harsh chemicals like chlorine and hydrogen sulfide in disinfection and purification processes. Over time, those chemicals can eat away at unlined steel and cause leaks and contamination.

Rubber lining also provides some resistance to microbial growth, further enhancing the safety and functionality of both the equipment and the water inside.

6. Utility and Power Plants

Biggest threat: High temperatures and chemical corrosion

Power plants, particularly ones that use fossil fuels, operate under extreme temperatures and corrosive environments. The rubber linings used in this sector mainly protect boilers, condensers, and cooling water pipes from corrosion caused by chemical-laden fluids, high heat, and steam.

In coal and gas power plants, rubber linings protect systems from fuel combustion byproducts.

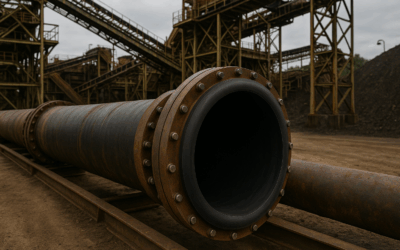

7. Mining Industry

Biggest threat: Material abrasion

The mining industry is notorious for its abrasive, aggressive environments. Equipment like slurry tanks, chutes, and pipelines are constantly exposed to abrasive materials, like ores, that can cause severe wear and tear. Without proper protection, these materials would wear their containers down rapidly, requiring frequent maintenance and replacement.

8. Steel Mills

Biggest threat: Chemical corrosion and high temperatures

The steel industry often deals with high temperatures and corrosive chemicals. Take the pickling process for example. A chemical treatment is used to remove impurities, rust, and scale from the metal surface. The chemicals used here can cause significant chemical corrosion to the larger equipment at play.

9. Battery Plants

Biggest threat: Chemical corrosion

Battery plants, especially those that manufacture lead-acid batteries, are another major industry that relies on rubber linings. The highly corrosive sulfuric acid used in battery production can rapidly degrade steel equipment and cause spills and leaks. Rubber linings provide essential protection in chemical storage tanks and other processing equipment in these facilities.

Protect Your Equipment with the Industry’s Best

From chemical storage tanks in petrochemical plants to water treatment tanks in municipal facilities, rubber lining serves as the backbone to protect numerous industries and applications from equipment corrosion, abrasion, and chemical attacks. As facilities continue to evolve and face new challenges, rubber linings will remain a critical part of industrial operations, ensuring equipment longevity, environmental safety and responsibility, and lowered maintenance costs.

Our US RUBBER team is proud to support these industries (and more) with high-quality rubber lining designed to meet the most demanding specifications. Whatever industry you’re in, if you need rubber lining protection, contact us for a job well done.